5

AFTER 900 EUROPE’S DEFENSES AGAINST Viking and Saracen marauders gradually stiffened, containing, converting, and absorbing the Scandinavians, and pushing back the unconvertible Muslims by counteroffensive. In Spain, Christian kings slowly gained the upper hand over their Muslim rivals; a band of Norman French adventurers successfully invaded Arab-held Sicily in 1071; and in the last decade of the eleventh century, the religious outburst that fueled the First Crusade carried the European counteroffensive into Asia Minor, Syria, and Palestine.

Whether Christianity gained anything from the capture of Jerusalem is debatable, but the Italian maritime cities, in particular Pisa and Genoa, unquestionably profited from the seizure and colonization of the coastal towns of the Levant. The long-distance commerce in the luxury goods of the Orient carried on through these colonies played an important role in what Robert S. Lopez has called “the Commercial Revolution of the Middle Ages,” the economic surge in which the Italian cities were the energetic leaders.

The other military victories over the Muslims brought dividends hardly noticed at the time but of immense future significance: access to Islamic learning and technical knowledge. Toledo, taken by Alfonso VI of Castile in 1105 and converted into his new capital, proved a tremendous cultural prize, the decline of Baghdad having made it the leading center of Islamic learning.1 Sicily and southern Italy bestowed another treasure of scientific and technical information. The principal European gain from military success was thus not the expulsion of the infidels but the opportunity to mix with them. In Spain the strengthening of Muslim defenses by reinforcements from North Africa prolonged the interface by stabilizing the military and political front for a century.2

The Vikings, meanwhile, turned their attention westward, where Irish missionaries had discovered Iceland. Reconnaissance was followed by settlement of the large island, up to then inhabited only by foxes. From Iceland’s western shore another island could be discerned some 175 miles away. Eric the Red colonized Greenland in the 980s, and one of the first ships to sail for the new colony, commanded by Bjarni Herjulfson, missed its landfall in the fog and was blown across the Davis Strait to Labrador. Bjarni inspected the forested coast and without attempting to land became, in 986, the first known European discoverer of America. In the millennial year of 1000, Leif Ericsson undertook to follow up the discovery (using Bjarni’s own ship) by planting a colony there.3As an achievement, Leif’s voyage was unimpressive, merely another crossing of the Davis Strait. As a historic event it also proved insignificant. The colony vanished almost without a trace, and though other Viking ships visited North America in the following two centuries (mainly in search of wood for unforested Greenland), they made little impact.

Bjarni and Leif may not even have been Europe’s first discoverers of America; they may have been preceded by Irish missionaries, sailing their toylike skin-covered boats via Greenland to Labrador or Newfoundland.4 As a practical enterprise, any such project was doomed; Europe was not ready to discover America, which it did not yet need. The missionary effort, however, has a certain symbolic significance, as a reminder of the early roots of one of the great motivations of explorers.

In the centuries after Eric, Bjarni, and Leif, Europe was at last getting ready to discover America and to do much more. “From 950 on,” writes Robert Reynolds, “there was…growing manufacture of textiles, pottery, leather goods, and many other things. The list of articles manufactured gets longer and longer [as the tenth century gives way to the eleventh], the products get better and better. Prices go up in terms of money but down in terms of man hours because of more efficient management, the application of mechanical power, improvement in tools and machinery, and better transport and distribution.”5 Where Europe had formerly exported “low-grade, backward-area” products such as slaves and furs, by Leif Ericsson’s time it had begun shipping textiles and metal products to Africa and the Near East, and even to Asia. By 1200 it was sending high-grade woolens to Alexandria, Constantinople, and farther east, as well as bar iron, copper ingots, utensils, and arms and armor. Returning ships carried grain to Europe’s cities from Sicily and North Africa. A notable import was chemicals, especially alum, used by dyers to fix colors in the ever-expanding wool cloth industry.

In the north, several German towns situated on or with access to the North Sea—Cologne, Bremen, Hamburg—launched careers as major commercial carriers. By the year 1000 their merchants had won a privileged position in London for their “Hanse,” or merchant guild, in time gaining virtual exemption from customs by lending money to Richard Lionheart.6

In a word, Europe was turning from a developing into a developed region. The growth of industry meant the growth of cities, which in the eleventh and twelfth centuries began to abandon their old roles of military headquarters and administrative centers as they filled with the life of commerce and industry. Some, like Genoa, once Roman villages, mushroomed, while others, like Venice, appeared out of nowhere. Still others, calling themselves simply “New City” (Villanova, Villeneuve, Neustadt), were founded by progressive rulers. Instead of growing haphazardly, they were built on a plan, typically a grid pattern with a central square, church, and market buildings.7 Beginning in tenth-century Italy, businessmen and craftsmen in many cities established what they called “communes,” declaring themselves free men who owed allegiance only to a sovereign who collected taxes but otherwise left them alone. Astute lords granted charters exempting city dwellers from feudal obligations—“so that my friends and subjects, the inhabitants of my town of Binarville, stay more willingly there,” sensibly explained one lord.8 Under the rubric “Free air makes free men,” even serfs were declared emancipated if they maintained themselves in a city for a year and a day.

A central feature of the Commercial Revolution was the trade fair. Dating back to Roman times, the fair was kept alive through the early Middle Ages by maritime centers where native and foreign merchants could conveniently meet. The practice spread to inland towns in Italy and southern France; in northern France, St. Denis, near Paris, opened a highly successful annual fair in about 635. In the ninth century, many more were inaugurated, spreading in the tenth to Flanders and northern Germany. But by far the most famous and significant were the Fairs of Champagne, the region east of Paris. In the eleventh and twelfth centuries, the counts of Champagne organized them into an annual cycle of six fairs occupying the entire year, with safe conduct guaranteed to foreign merchants. The Champagne Fairs forthwith became the established rendezvous for merchants from Italy and Flanders.

The Middle Ages had inherited no effective credit instruments from the ancient world, which had never developed any. Furthermore, the Christian Church, in accordance with the Bible, condemned usury and defined it as the charging of any interest whatsoever. The revival of commerce and the transactions of the Champagne Fairs stimulated the invention of novel forms of credit designed to circumvent the Church’s ban. Italian merchants had already adopted one form, from Arabs, Jews, or Byzantines, thecommenda(also called the collegantia or societas), by which one partner undertook a voyage, borrowing all or most of the capital from the other partner, with profits divided according to a prearranged formula—an insurance device as well as a loan and a temporary partnership. Another form of credit developed simultaneously was the cambium maritimum, in which a merchant undertaking an ocean voyage borrowed capital in one place in one currency, to be repaid in another place in another currency, the interest concealed in the rate of exchange, repayment contingent on safe arrival of the ship. The Champagne Fairs converted this form of loan into a land arrangement, omitting the element of marine insurance and creating both a way to earn interest and a means of transferring funds abroad, thus making possible the transaction of business by remote control.9

Along with the cities, the farming regions that fed them grew. A European population between the Baltic and Mediterranean estimated at 27 million in A.D. 700 had reached 60 or 70 million by 1200.10 In Carl Stephenson’s words, the creation of “a bourgeois class such as the Roman Empire had never seen” gradually brought with it “the emancipation of the rural masses that made possible our modern nations.”11

Behind this demographic and economic surge lay technical innovations: a radically new system of organizing agricultural work, newly expanded power sources, dramatic new techniques in building construction, and other novelties undreamed of by Greeks and Romans.

Open Fields and Waterpower

By the central Middle Ages, much of the countryside was dominated by two complementary systems: on the level of the village and its peasant inhabitants, the form of organization of work known as the “open-field system” on the level of the lord, the form of management called the “manorial system.”

The manor, often not coincidental with the village (which might contain more than one manor, or be only a part of a manor), was an estate held by a lord. In its classic form it consisted of land directly exploited by the lord (the demesne) and peasant holdings from which he collected rents and fees, usually including labor services. The combination of demesne and tenants probably dates from the early Middle Ages, but it had its first specific documentary mention in the ninth century in northern France and in the tenth century in Italy and England. By the eleventh century it was well established in Europe.12

Snow highlights house sites, gardens behind them, and surrounding fields in aerial photograph of deserted open-field village of Wharram Percy, Yorkshire. [Cambridge University Collection of Air Photographs.]

The origins of open-field agriculture are lost in the obscurity of the tenth and eleventh centuries, whose scanty documentation offers only scattered scraps of information. By the time the more abundant records of the twelfth century provide light, the system was already mature.

Several factors may have contributed to this second agricultural revolution. One was population growth, fragmenting family holdings through the custom of dividing inheritance among children or among sons. A second was “assarting,” cultivating new land or reclaiming wasteland. When a group of peasants banded together to clear forest or drain swamp, they divided the resulting “assart” into strips convenient for plowing. A third factor was the heavy plow, which favored working long strips over square plots, to reduce the number of turnarounds, especially awkward with multiple-animal teams. In time, broad areas of Britain and continental Europe were occupied by villages surrounded by two or three large fields made up of cultivated strips clustered in “furlongs” fitted to the contours of the terrain. Each year one field was left fallow, the remaining land cultivated with spring and fall crops. Crop rotation was biennial in a two-field system, triennial in a three-field.

The strips were not apportioned equally; some peasants held several, some few, some none. The lord’s demesne usually consisted of a large number of strips, cultivated by the serfs (villeins, in England) in payment for their holdings. Every tenant, free or serf, who held strips held them in both or all three fields, to ensure a crop every year.

Crop rotation and fallow were not new devices. What was new was the way they were organized and regulated. Plowing and planting, harvesting and opening the fields to grazing, all had to be done in concert. The necessary decisions were made not by the lord but by the peasants, whose cooperation became the hallmark of the system. While meeting their obligations of labor and money payments to the lord, the villagers created their own self-governing apparatus based on a set of bylaws that ruled their working lives. The system was neither free enterprise nor socialism; it was sui generis, one of the unique creations of the Middle Ages.13

The heavy plow and the new horse harness fitted well into the open-field system, even if the two devices probably did not, as was once believed, play the decisive role in its establishment. The plow heightened the need for cooperation, since not all peasants who held land owned plows or plow animals. Expanded use of the horse stimulated cultivation of oats, a spring crop appropriate to open-field rotation. The fact that the horse was fed in the barn made his manure easy to collect and thus increased the use of fertilizer, while the spring legumes (peas, beans, and vetches) restored nitrogen content to the soil. Another fortuitous benefit of the system emerged in the ridge-and-furrow pattern built up by strip plowing. In the wet but erratic climate of northern Europe, the ridge tended to stay dry in wet seasons and the furrow to stay moist in dry seasons, providing a kind of crop insurance.

Not all medieval agriculture was open-field. In some regions isolated homesteads were the rule. Other systems existed, notably the infield-outfield system, in which a small “infield” was worked intensively with the aid of fertilizer while the large “outfield” was held as a land reserve.

The population surge stimulated another response in the Low Countries, where an unending war against the sea had been carried on since the seventh century. The Frisians and other coastal dwellers depended for life and livelihood on precarious seawalls four or five feet high, which they maintained with great difficulty until the monks of the new Cistercian Order came to the rescue. An arrangement was worked out by which the land was deeded to the monasteries, then leased back to its cultivators while the monks took responsibility for upkeep of the dikes. Lay brothers performed the labor despite recurrent overwhelming floods. A chronicler of one such flood left an arresting image: a floating tree, to which clung a man, a wolf, a dog, and a rabbit.14

Another new monastic order, the Carthusians, dug the West’s first deep-drilled well in 1126, at Lillers, in Artois (whence the name “artesian” well). A shaft only a few inches in diameter was sunk through impermeable strata to reach a stratum of water under pressure, producing a well that needed no pumping. The technique—percussion drilling, a succession of blows struck on a rod with a drilling tool on its end—had long been used in China. Whether it was borrowed or independently invented in Europe is conjectural.

The tenth and following centuries witnessed steady progress in reclamation of unproductive areas via drainage, irrigation, and land clearance. Northern and western Europe, once sparsely inhabited, filled in. By the end of the twelfth century, the fields, meadows, and woodland of thousands of villages abutted one another. All of them cultivated grain, and most ground it by water mill. The rapidly multiplying written records supply a wealth of statistics, of which perhaps the most telling is the figure given in Domesday Book, the survey prepared in England in 1086 at the order of William the Conqueror. A century earlier, fewer than 100 mills are recorded in the country; Domesday Book lists 5,624 (low, since the book is incomplete). Georges Duby calculates that the figure indicates a mill for every forty-six peasant households and points out an implication: a substantial rise in consumption of baked bread in place of boiled, unground porridge.15 Continental records tell a similar story. In one district of France (Aube), 14 mills operated in the eleventh century, 60 in the twelfth, and nearly 200 in the thirteenth.16 In Picardy, 40 mills in 1080 grew to 245 by 1175.17 The boat mills invented by Belisarius, moored under the bridges of early medieval Paris and other cities, began in the twelfth century to give way to structures permanently joined to the bridges.

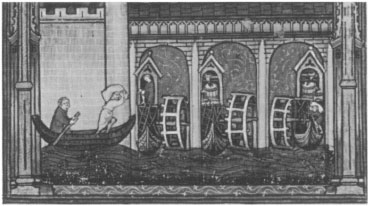

Water mill with overshot wheel and eel trap in the millstream. [British Library, Luttrell Psalter, Ms. Add. 42130, f. 181.]

The waterwheel never played a major role in the Muslim world, not for lack of knowledgeability—Muslim hydraulic engineering was far ahead of European—but for want of fast-flowing streams. Large dams and intricate irrigation systems aided agriculture in Moorish Spain, but the waterwheel was used only for grinding grain and raising water.18 In Christian Europe, in contrast, the vertical wheel, including the powerful overshot type, was finding important new applications. Once more the monasteries led the way. The great Benedictine abbey of St. Gall in Switzerland pioneered the use of waterpower for pounding beer mash as early as 900.19 The new Cistercian reform movement launched in 1098 at Cîteaux, in Burgundy, carried on the Benedictine tradition of promoting technology by founding waterpowered grain mills, cloth-fulling mills, cable-twisting machinery, iron forges and furnaces (where the wheels powered the bellows), winepresses, breweries, and glassworks. The edge-runner mill, long known to China, was adopted for more efficient pressing of olives, oak galls and bark for tannin, and other substances requiring crushing.20

The contemporary biographer of St. Bernard, leader of the Cistercian movement, illustrated the respect accorded the waterwheel; in describing the reconstruction of the saint’s abbey of Clairvaux in 1136, he neglected the new church but included an enthusiastic account of the monastery’s waterpowered machines.21 The first waterpowered iron mills in Germany, England, Denmark, and southern Italy were all Cistercian.22

One of the earliest widespread industrial applications of the waterwheel was in fulling cloth; the trampling feet of the fullers were replaced by heavy wooden hammers lifted and dropped by the turning waterwheel. One effect was to draw the fullers into the countryside, where they further profited by freedom from the sometimes restrictive regulations of the towns. Another effect was the spread of the knowledge of gearing.23

Hemp production required a similar pummeling action to break up the woody tissues of the dried stalks and free the fibers for manufacture of ropes and cords. The existence of a waterpowered hemp mill is documented in the Dauphiné, in southeastern France, as early as 900.24

By the late eleventh century, waterpower was pounding, lifting, grinding, and pressing in locations from Spain to central Europe. In several applications of waterpower, notably in lifting and dropping hammers, the camshaft made its earliest Western appearance, diffused from China (as Joseph Needham believes) or independently invented, as seems not unlikely. The cam, a small projection on the horizontal shaft of a vertical waterwheel, caught and lifted the falling hammer, which dropped of its own weight. Usually a pair or more of cams on the same shaft operated alternately.25

The more abundant records of the twelfth century throw scarcely more light than the scanty ones of the eleventh on the types of waterwheel that were built, but increasingly the efficient vertical overshot wheel justified its initial cost when used to grind grain, and its superiority was persuasive in industrial applications. Modern calculations show that the ancient donkey-or slave-powered quern of Rome produced about one half horsepower, the horizontal wheel slightly more, the undershot vertical about three horsepower, and the medieval overshot wheel as much as forty to sixty.26 A continuing weakness of waterwheel installations was their reliance on fragile wooden parts, gears as well as camshafts. On the other hand, a broken wooden piece was easily replaced by a peasant craftsman. The cost of iron made metal gears a luxury even as late as the eighteenth century.

The proliferation of gristmills may have owed as much to the role that they had come to play in the lord-peasant relationship as to their labor-saving value. An aspect of the “ban,” the lord’s local power, became one of the most resented of his privileges: the obligation of unfree peasants to have their grain ground at the lord’s mill, at the cost of a multure, commonly one thirteenth of the grain or flour. Despite peasant protests, the profitable ban was gradually extended to oil and wine presses, bake ovens, and iron forges. The peasants’ resentment was not only against the payment of multure but against the inconvenience of taking the grain to the mill and waiting in turn. The right to “jump the queue” was reserved to free tenants willing to pay a fine to grind “next after the grain which is in the hopper.” Many peasants surreptitiously operated illegal hand querns, while others went back to eating porridge.

The gristmill often represented the most visible symbol of a wider oppression, as in the rebellion of the inhabitants of St. Albans. Seeking to secure a charter of urban liberties from the lord abbot, the townspeople openly and defiantly milled their own grain with their hand querns. When the rising was suppressed, the abbey confiscated the querns and incorporated the millstones into the floor of the monks’ parlor as a trophy of victory. Fifty years later, during the Peasants’ Rebellion of 1381, the people of St. Albans dug up the monks’ floor and distributed the fragments of the stones among themselves as tokens of solidarity, in the spirit, according to St. Albans chronicler Thomas Walsingham, of sharing the sacrament. Struggles over hand mills in other places likewise signaled deeper grievances about taxes, labor services, and legal status.

Some scholars have argued that the lord’s gristmill was economically viable only because of the ban and that without the ban the tenants would have chosen to use their own cheaper and more convenient hand mills. Evidence to the contrary, however, is found in the existence of a special rate of multure charged to free tenants, who were not under obligation to use the lord’s mill. This rate, typically one twenty-fourth, a little more than half that charged unfree tenants, seems to represent the true, free-market value of the service. Recent scholarship has also discovered the presence of independent water mills, outside the lord’s control and competing with his mills, held by free tenants and even by villeins, who charged their own multure fees and kept the profits. Such mills seem sufficient proof that compulsion was not the only basis for the gristmill and that powered milling of grain made compelling economic sense even without the ban.27

Waterpower spurred construction of dams, at first on a small scale to create millponds and millraces but increasingly on a larger scale. The Arabs, who in their era of conquest had learned about dam building from India and the Near East, brought their knowledge to Spain, where a few Roman dams still operated. These they kept in repair, adding dams of their own, such as the great structure at Murcia, 425 feet long and 25 feet high, its rubble core faced with masonry blocks.28 By the twelfth century, dam building had crossed the Pyrenees in a spectacular form. At Toulouse, forty-five mills were driven by streams controlled by three dams in the Garonne. The principal one, mentioned in a document of 1177, was probably the largest dam then existing. Thirteen hundred feet long, it was built diagonally across the river by ramming thousands of giant oak piles into the riverbed to form palisades that were then filled with earth and stone.29

Millraces similarly expanded into hydropower canals in the twelfth century. The monastery of Clairvaux dug a 3.5-kilometer (2-mile) millrace canal from the river Aube to the abbey, while the Cistercians of Obazine chipped one 1.5 kilometers through solid rock.30

Medieval engineers were the first to exploit the waterpower supplied by ocean tides. Tidal mills are recorded in Ireland as early as the seventh century, in the Venetian lagoon before 1050, near Dover in Domesday Book, and a little later in Brittany and on the Bay of Biscay. The practical value of tidal mills was limited by their short operating periods (six to ten hours a day), the eccentric working hours imposed on the millers, and the vulnerability of the mills to storm damage.31

In the last twenty years of the twelfth century, an entirely new prime mover appeared simultaneously on both sides of the English Channel and the North Sea. Nothing like the windmill in its vertical European form had ever been seen. Though some scholars believe it to have derived from the horizontal windmill of Persia, perhaps diffused through Muslim Spain, the weight of evidence favors an independent origin, possibly in East Anglia, where it replaced unsatisfactory tidal mills and supplemented the scanty waterwheels. Reversing the waterwheel’s arrangement, the windmill placed the horizontal axle at the top of the structure, to be turned by sails, gearing it to the millstones below. The immediate problem of keeping the sails faced into the wind (or out of it in a gale) was solved by balancing the mill on a stout upright post, on which it could be turned, none too easily, by several sturdy peasants gripping a large boom.

Crafts in Town and Country

While agriculture still absorbed much the largest share of human labor, the number of handicraft workers and the volume and diversity of handicraft production increased significantly in the central Middle Ages. By far the most universal and widespread craft was that of cloth making, which experienced a major change in the organization of work. Throughout antiquity and the early Middle Ages it had been the province of women working in the gynaeceum; now, as slavery waned and the gynaeceum disappeared, the craft was decentralized to the family unit. The male head of the household was the weaver; the women prepared and spun the yarn for his loom.32

A fourteenth-century windmill. [British Library, Stowe Ms. 17, f. 89v.]

By the twelfth century, the loom the weaver operated was a new mechanized model, probably a descendant of the Chinese silk loom. Horizontal rather than vertical, it allowed the weaver to sit while he worked. In operating the old vertical warp-weighted loom, the weaver, standing, had advanced or retarded sets of warp threads by moving the heddle bar forward or backward in its brackets; now this operation was performed by a pair of foot treadles, leaving the operator’s hands free. To pass the weft yarn through the shed created by the heddles, he used another innovation, the boat-shaped shuttle, holding a bobbin wound with thread.33

Horizontal loom, c. 1250. The weaver “leans upon two stirrups” (the treadles, which control the heddles by means of an overhead pulley arrangement), while he passes back and forth the newly invented boat-shaped shuttle. (The plane of the warp threads is parallel to the floor, despite the faulty perspective.) [Trinity College, Cambridge, Ms. 0.9.34, f. 34v.]

To the English scholar Alexander Neckam (1157–1217), the weaver at the horizontal loom was “a horseman on terra firma who leans upon two stirrups,” the treadles, which were attached to a pulley arrangement above the loom called the “harness.”34The shuttle was weighted and contained “an iron or wooden bobbin,” from which the weft thread was drawn as “the one hand of the weaver tosses the shuttle to the other, to be returned vice versa.” As he completed a row, the weaver “beat down the work accomplished.” Alexander pictured a woman, a textrix, working alongside the weaver, combing the wool, spinning the yarn, smoothing the finished cloth, and helping the time pass by singing “sweet songs” to the man at the loom.35

From about 1000, wool cloth manufacture for the market had begun to concentrate in certain regions. Especially prominent was Flanders, where the favorable conditions included a soil congenial to dye plants, an abundance of the cleansing agent fuller’s earth, and proximity to England, the prime source of fine fleece. As in Roman times, fulling and dyeing were specialized trades. Traditionally, the fuller trampled the cloth in a trough filled with water, fuller’s earth, urine or wine dregs, lime, and sand, changing the water several times. The cloth was hung to dry on a wooden frame, the “tenter,” fastened by hooks that could be adjusted to stretch the fabric to the right length and breadth and then teaseled to raise the nap.

Dyeing might be done at different stages in manufacture: before the yarn was woven (“dyed in the wool”), after fulling, or sometimes after the cloth was sold. Among the most demanding of cloth techniques, it required a knowledge of fabrics, dyes, and mordants (color fixatives) and by the twelfth century had been taken over almost completely by men.36 Cloth or yarn was soaked in a tub of hot water and turned at intervals with a pole. Red and blue were the predominant colors, produced respectively from the madder root and the woad leaf. Since woad leaves could be plucked several times a year, blue dye was cheaper.37

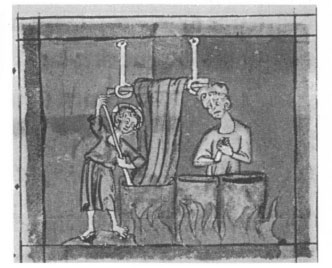

The boy Jesus as an apprentice dyer, c. 1300. [Bodleian Library, Ms. Selden Supra 38, f. 27.]

The wool cloth cities of the eleventh and twelfth centuries were commercial rather than industrial centers, collecting cloth from neighboring villages to be sold in Baltic and Mediterranean markets.38 The entrepreneurs who carried on this trade formed associations called “merchant guilds,” first in tenth-century Italy. The origins of the merchant guilds were in religious and charitable brotherhoods and “associations of fellow drinkers” (Robert Lopez), but they became powerful monopolies which in many cities dominated the political as well as the economic scene.39 In Florence members of the Arte di Calimala, who clustered on the Via Calimala, bought unfinished cloth at the Champagne Fairs in France and transformed it into a luxury commodity by their superior finishing and dyeing. Their dyes were imported and expensive: red from “kermes” or “grana,” derived from certain dried insects; violet from orchil, a lichen; crimson and purple from brazilwood, an East Indian tree. Their “scarlets,” particularly prized, were not necessarily red but sometimes gray, dark gray, dark blue, or black, the common element a certain proportion of kermes. Costing as much per length as a skilled mason could make in three years, the scarlets were for the wealthy elite: “popes, emperors, archbishops, princes—and…Flemish civic aldermen” (John Munro).40

Wool dominated the textile industry, but linen retained importance, based on a technology long known to the West. At first practiced in the towns, linen making was shunted to the outskirts or the countryside when the retting ponds, where the woody flax tissues were soaked to separate them from the fibers, became a public nuisance rivaling the noisome operations of the tanners and butchers.

By the twelfth century, cotton and silk were also being manufactured on a substantial scale in Italy. Sicily’s cotton industry, inherited by the Norman conquerors from the Arabs, was supplemented in the early twelfth century by new centers of manufacture in northern Italy. Both products and techniques imitated those of the Arabs, with two differences. Where the Arab industry was largely government controlled, the Italian remained in the hands of private entrepreneurs, and where the Arab industry stretched from Baghdad to Spain, near its widely scattered sources of raw materials, the Italian was concentrated in the Po plain, whither it imported raw cotton from overseas and where it soon became for European cotton what Flanders was for wool.

Italian craftsmen ginned their cotton with the Indian churka, acquired from the Arabs, a device not improved on until Eli Whitney’s invention. It consisted of two grooved wooden rollers, turned with a crank, revolved against each other in opposite directions to remove the seeds. The bolls were beaten, an operation facilitated by the introduction in the early twelfth century of the arco, a wooden bow suspended from wall or ceiling, its taut cord buried in a pile of raw cotton. When the cord was tapped with a mallet, its vibrations caused the cotton bolls to open and the fibers to separate. The cotton was combed or carded and spun, and half of it “warped,” grouped into uniform lengths to be positioned on the loom as warp threads. Weaving was followed by bleaching, dyeing, washing, and stretching.41

In the eleventh century, most of Europe’s silk was still imported from Islamic lands or Asia, despite a sizable silk industry in Byzantium. The Church was a large customer, favoring silk as a wrapping for the relics of its saints and ignoring occasional Arabic inscriptions: on St. Cuthbert’s shroud in Durham Cathedral, “There is no God but Allah” on that of St. Josse of Brittany, “Glory and rising fortune to the commander Abu Manu Haidr; may Allah lengthen his life.”42 By the twelfth century, silk manufacture too began to move into Italy. Venetians had already established their own silk-weaving shops in Constantinople, where they enjoyed a privileged position; the next step was to introduce silk craftsmen into Italy. Chronicler Otto of Freising tells us that in 1147 Norman king Roger II of Sicily brought weavers of silk from several Greek cities to Palermo. A third center, Lucca, had specialized in the silk trade in the eleventh century and succeeded in founding its own industry in the twelfth.43

Other industries besides textiles tended to concentrate by city or region: fine glass on the island of Murano (Venice), pots and pans in Flemish Dinant, arms and armor in Nuremberg and Milan. By the twelfth century, Milan was “a kind of general arsenal town” (Robert Reynolds) producing in large quantities armor, weapons, horseshoes, nails, and crossbow bolts.44

Most cities were less specialized, however. Gawain, hero of Chrétien de Troyes’s Arthurian romance, Le Conte del Graal, gazes at a town with its “many fine people” and notes their vocations: “This man is making helmets, this one mailed coats; another makes saddles, and another shields. One man manufactures bridles, another spurs. Some polish sword blades, others full cloth, and some are dyers. Some prick the fabrics [raise the nap] and others clip [shear] them, and these [men] here are melting gold and silver. They make rich and lovely pieces: cups, drinking vessels, and bowls, and jewels worked in with enamels; also rings, belts, and pins.”45 Knightly Gawain’s eye is attracted to the crafts of war and luxury, but he might have noted some hundred others in a prosperous twelfth-century town, including cordwainers (shoemakers), cobblers (shoe repairers), tailors, carpenters, leather workers, coopers, masons, butchers, brewers, and in smaller numbers hatters, harness makers, cartwrights, purse makers, and glove makers. The goldsmiths that he mentions worked not only gold and silver but tin, brass, and copper, hammering, sawing, smoothing, polishing to fashion rosaries, cups, ornaments, and the gold leaf that adorned illuminated manuscripts. Tanners scraped hides, rubbed them with dung to soften, and either soaked them in tannin baths with oak bark, oak galls, or acacia pods or transformed them into white leather by tawing—treating with alum and salt. The techniques were known to the ancients and not substantially improved until the nineteenth century.46

Thus, although only cloth making achieved the status of a large-scale commercial industry, handicraft production was a flourishing institution by the twelfth century, and despite the prejudice of the landed aristocracy against those who worked with their hands to earn money, it enjoyed a considerable measure of respect. This respect reflected the distinctly medieval character of the work, combining concern for quality with pride in individual craftsmanship. Every product was in a sense a work of art. Tools, often made by the craftsmen themselves, were precious and were passed down from father to son or bequeathed in wills to favored colleagues.

In the twelfth century, the guilds of the merchants were joined by guilds of craftsmen. These craft guilds, with their hierarchy of masters, journeymen, and apprentices, had two principal functions: mutual aid and control of production—quality, price, working hours, and wages. Each guild monopolized its craft, but at first membership was relatively easy to attain, and the controls exercised were moderate. The charge that the craft guilds resisted technical progress applied only to a later age and even then derived mainly from the guilds’ concern for handicraft quality. “In so far as [the craft guilds] succeeded in regulating growth without stopping it,” writes Robert Lopez, “they spared their humbler members the extreme sufferings that were inflicted on the slave gangs of antiquity and the factory hands of the early Industrial Revolution.”47 New machines and processes, designed to speed production and save labor, inevitably provoked the craftsman’s suspicion that quality would suffer along with his livelihood. Nevertheless, he was by no means always blind to the value of technical innovation. John Harvey credits the medieval building trades with “the introduction of new inventions, new processes, and new aesthetic ideas after about 1100.”48

Among the craft innovations in the central Middle Ages was the drawplate, a device that aided blacksmiths in fabricating wire for chain mail, until then laboriously hammered out at the forge. The piece of heated iron was drawn through successively smaller holes, a process that remained only to be mechanized. Another innovation took place as soap became an article of commerce, by the substitution of olive oil for animal fats. As a result the industry migrated south from its early center in Scandinavia to Marseilles, Venice, and Castile.49

The only significant modification ever made in the art of brewing came with the introduction of hops, as early as the tenth century in some places, as late as the fourteenth in others. Hops imparted the faintly bitter flavor that gradually won preference over the fruity taste of the older brew and also served as a preservative. Among medieval crafts, brewing had two distinctive characteristics. Its universality in beer-drinking regions, second only to spinning and weaving, made it a village as well as a town vocation; and in both town and village a high proportion of its practitioners were women.50

Apart from brewing, the craft world was dominated by males, but in the family production unit that prevailed, wives shared work with their husbands and widows often succeeded them. Some married women worked at trades of their own; single women occasionally worked at crafts as femmes soles and enjoyed a status of recognized equality.51

Two crafts that came to be practiced in villages and on rural estates nearly everywhere were those of carpenter and smith. The village carpenter was probably as old a feature as the village itself, fashioning all kinds of implements as well as components of buildings, bridges, and wagons by splitting, trimming, sawing, hewing, and shaving the logs he cut from the neighboring forest. The smith, long primarily armorer for the castle elite, shifted to the village only as demand for his services to agriculture grew. A study in Picardy showed no trace of a village smith before 1125 but counted thirty by 1180.52 The combination of the two crafts was indispensable for making and repairing agricultural implements—plows, spades, mattocks, hoes, axes, billhooks, sickles.

Commonly the two trades collaborated, since most of their products combined wood and iron. The carpenter used nails handmade by the smith for his fastenings, usually boring a hole first with an awl.53 Saws, hammers, axes, adzes, drills, and knives required precision work by both smith and carpenter. Heating the workpiece at his forge, the smith hammered it on an anvil mounted on a stout trunk of wood, using sledgehammer (often wielded by an assistant or apprentice), lighter hammers, tongs, pritchel (punch), bellows, and file, besides a stone trough for quenching and a grindstone for sharpening and smoothing. Chisels were either “cold” or “hot”—designed to work pieces cold or red-hot—the cold chisel needing a harder edge. Tempering by repeated heating and quenching gave hardness and ductility but was time-consuming; only tools used on stone or metal were given a hard temper. Precision was strictly a matter of hand-eye coordination. A file was made by neatly striking a succession of closely spaced blows on a flat piece of heated iron with a sharp hammer. Saws also demanded patience and skill to produce sharp and even teeth along with overall hardness and flexibility. The saw was a carpenter’s tool; the peasant’s cutting tool, the ax, was easier to make.54

As building construction and commerce increased, the smith acquired important new customers: masons (mallets, picks, wedges, chisels, cramps, stays, tie-rods, and dowels); carters and wagoners (iron parts); millers (iron components of hydraulic machinery); and shipbuilders (nails and fittings).

Besides town and village, the great lay estates retained their own craftsmen—armorers, fletchers (arrow makers), smiths—while the monasteries maintained regular workshops where master glaziers and enamelers as well as goldsmiths exercised their arts. A description of one such monastic workshop is a feature of a unique treatise, Europe’s first technical manual, De diversis artibus (On diverse arts), composed in the first half of the twelfth century by Theophilus Presbyter (Theophilus the Priest), believed to be a pseudonym for a Benedictine monk named Roger of Helmarshausen, known for his metalwork artistry.55

Armorer at work: a spinoff from the blacksmith’s craft. [Trinity College, Cambridge, Ms. 0.9.34, f. 24.]

Unlike the numerous authors of encyclopedic, alchemical, and even practical manuals of the day, Theophilus was distinguished by his reliance on knowledge gained from firsthand experience. Addressing himself to “all who wish to avoid and subdue sloth of mind and wandering of the spirit by useful occupation of the hands and delightful contemplation of new things,” he divides his manual into three books. In the first, “The Art of the Painter,” he gives minute directions for making a variety of pigments, along with varnish, gold leaf, and ink. His recommendation of “Byzantine parchment” is probably the first documentary reference in the West to paper. Book Two, “The Art of the Worker in Glass,” describes a scale of operations that implies a work force of at least twelve and cites many specialized tools, including the blowpipe. Instructions follow on glass furnaces, proper mixtures of ashes and sand, manufacture of glass sheets, flasks, goblets, and windows, and repair of glass vessels.

But Book Three, “The Art of the Metalworker,” is clearly nearest the author’s heart. Devoting twice as much space to metalwork as to the first two subjects combined, Theophilus begins with a detailed description of the windowed workshop, partitioned into rooms for casting and working base metals, gold, and silver, each with its own specially designed workbenches and forges. He tells how to fashion bellows from ram skins and describes anvils, hammers, tongs, pliers, drawplates for wire, files, punches, chisels, and other implements. Theophilus gives “the earliest good description of the very ancient art of cupellation,” the oxidation of lead to separate out gold and silver.56 Only rarely does he wax fanciful; in his recommendation of goat’s urine or that of “a small red-haired boy” for quenching hot metal, he follows a “long and honorable” tradition of medieval metallurgists (Nadine George).57

All the punching, sinking, chasing, engraving, and repoussé that Theophilus so affectionately describes depended for its success on the skill and experience of the operator, expressed through his array of hand tools. Despite the implied use of a crank for rotary motion, nowhere does any large machine intrude, with the possible exception of a sort of lathe to shape molds in (bronze) bell founding. The sole reference to mechanical power is to the wind employed by the pipe organ.

In the twelfth century, much of metal production, from digging the ore to hammering out the finished product, remained a matter of laborious manual effort. Surface deposits of iron ore were no longer sufficient, and pits, trenches, and tunnels were driven into the earth, especially in central Europe. Slaves had disappeared from mine and forge, but large-scale capitalist organization of work, with its scope for power technology, lay in the future. The form that organization took in the “customs of miners” of central Europe and north Italy was characteristically medieval. First written down in 1185 in Trento, the “customs” followed the pattern of manorial agriculture: a share of each seam of ore was assigned to each family of miners, while decisions as to working methods, hours of work, and division of profits were made collectively by representatives of the miners and of the prince or landowner who was their lord.58 Preciousmetal miners were paid in ore, which they sold to waiting gold-and silversmiths at the end of each day.59

A Bible in Glass and Stone

Much of the craft described by Theophilus Presbyter reflects the contemporary enrichment of churches and monasteries by window glass, painting, and metalwork. Lords and merchants contributed gifts and bequests to benefit their souls, guilds donated windows showing the guildsman at work at his craft,* and pilgrims made contributions in honor of saints’ relics. The wave of philanthropy merged with a series of architectural inventions in the flowering of a new style of church architecture. Whatever their religious meaning, the towering new cathedrals signaled affluence. Of the eighty new-style cathedrals built in France from 1150 to 1280, a large proportion rose in the prosperous cloth towns of the North.60

The new architecture had its earliest beginning in the tenth century, in Burgundy. There the great abbey of Cluny, founded in 920 to spearhead reform of the old Benedictine Order, rebuilt its vast mother church (c. 980), taking note of two recent tendencies in Western Christianity: the custom of daily mass and the cult of the saints. At the eastern end of the abbey church, an ambulatory, or semicircular passage, was added, with chapels radiating off it for celebration of masses and preservation of saints’ relics. Elsewhere, new churches provided extra chapels by extending their side aisles past the transept.61

At the same time, better ways of supporting the massive Roman barrel vault were sought. From such Roman monuments as the Baths of Caracalla, builders revived the groin vault, formed by making two semicircular arches intersect at right angles, so that the weight of the vault rested on four massive corner columns instead of on two walls. An alternative was to rest the vault on transverse arches, that is, a row of arches running along either side of the nave. The result was the eleventh-century Romanesque triple vault, in which two narrow side-aisle vaults flanked the broader and higher nave vault, forming a mutual support system. As builders acquired fuller mastery of their technique, Romanesque vaults widened and rose.62 A second rebuilding of the church at Cluny in 1088 (Cluny III to modern architectural historians) created a nave 40 feet wide and 98 feet high, while a new church built at Speyer, on the Rhine, measured 45 feet in width and 107 in height.63

Back in the sixth century, Pope Gregory the Great had made a plea for depicting scriptural scenes on church walls for the benefit of the unlettered faithful. A synod at Arras in 1025 reiterated the recommendation, for “this enables illiterate people to learn what books cannot teach them.” But wall paintings in barrel-vaulted churches were hardly discernible in the dim light. When the nave was raised above the side aisles, a row of windows could be added, but too high to contribute much illumination.64

Thus church builders were pressed to create larger churches, with more complex floor plans and better light. The economic expansion of the eleventh and twelfth centuries underwrote a period of tireless experiment and rewarding discovery in masonry construction. The architectural style that emerged grew out of need, inspiration, and the accumulation of technical resources. Foremost in importance of the last were three engineering devices: the pointed (ogival) arch, the rib or cross-rib vault that derived from it, and the flying buttress that lent it external support. All three were developed separately in Romanesque buildings before being united to form what came to be called, much later and quite inappropriately, “Gothic” architecture.

Nave of Durham Cathedral, combining Romanesque side arches in the nave and the triforium gallery with a Gothic cross-rib vault. [Royal Commission on the Historical Monuments of England.]

The pointed arch is now believed to have originated in India and to have migrated westward to reach Italy by the eleventh century. In 1071 a porch (narthex) of the new abbey church at Monte Cassino, birthplace of the Benedictine Order, was given pointed arches and rib vaults. The result was a triumph. By distributing the weight of the vault to a skeletal structure of vertical columns, it converted walls from supporting elements into mere panels and opened the possibility of large window spaces. Not long after, the Norman conquerors of England introduced rib vaults in the choir of the cathedral they had begun at Durham in 1093, though keeping the arches round; later, in the nave, they made them pointed.

Meanwhile, Cluny’s Abbot Hugh visited Monte Cassino before embarking on Cluny III, a structure still Romanesque but incorporating several pointed arches. These caught the eye of visiting Abbot Suger, of the royal abbey of St. Denis, where the kings of France were buried. As he recorded in a memoir that provides rare documentary light on the development of Gothic construction, Suger was looking for ideas for the rebuilding of his own abbey. Beginning work in 1135, he discarded the Romanesque style completely, signaling the full arrival of the dramatic new architecture: pointed arches, rib vaulting, soaring vertical lines, and enormous window spaces filled with stained glass, including a huge rose window in the west front.65

Suddenly Pope Gregory’s wish found a dazzling fulfillment. “A blaze of glass windows” was a twelfth-century chronicler’s description of Canterbury Cathedral following its rebuilding in the new style.66 A few conservative churchmen even found the new brilliance too glaring, but the public enthusiastically applauded the stained glass, manufactured in the forest, where fuel and raw materials were available and where the smoke provoked no protest.

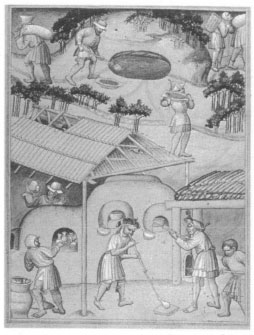

Glassblowing, from a twelfth-century version of a work of Hrabanus Maurus. [Division of Rare and Manuscript Collections, Carl A. Kroch Library, Cornell University.]

Twelfth-century glassmaking followed long-established methods, although sodium ash from Europe’s hardwood forests had replaced potassium ash as principal ingredient. Two parts of wood ash (beechwood preferred) mixed with one part sand were heated in a furnace to a moderate temperature that produced a reaction between the sodium carbonate in the ash and the silica in the sand, a process called “fritting.” The “frit” was melted by a higher temperature and blown with a long iron tube. To produce window glass, the resulting bubble was shaped into a cylinder, the ends cut off, and the cylinder split down the long axis and flattened to a sheet. An eleventh-century manuscript illustration shows a furnace with three tiers, the lowest for fritting, the middle for melting, and the top for annealing, the process of controlled cooling.67

Like metallurgy, glass manufacture was a rule-of-thumb process, relying not on knowledge of chemistry but on trial and error. At first colors were obtained by varying the proportions of raw materials and by changing the melting time—such at least is the conclusion drawn from the description of Theophilus Presbyter. “If [the melt] happens to turn a tawny flesh-like color,” Theophilus wrote, “heat for two hours and it will become reddish-purple and exquisite.” Later the addition of metallic oxides made colors truer and more easily controlled: cobalt for blue, manganese for purple, copper for red, iron for yellow. More difficult to achieve, and in fact for a long time unobtainable, was clear glass. By cutting up the sheets of colored glass, glaziers could create designs, which almost at once became pictorial. Out of accident and need, art was born.68

An early-fifteenth-century Bohemian forest glasshouse. The main furnace is being stocked by the small boy on the right, while annealing furnace is on the left. Melted glass is collected (second from right) and blown (center). Behind the furnace, the master glassmaker inspects a vessel. In the background, sand is being quarried and brought to the furnace. [British Library, Ms. Add. 24189, f. 16.]

Glassmakers clustered in areas with suitable forests—such as Normandy, Burgundy, Lorraine, Germany, and Flanders—but traveled freely to meet demand for their services. Most of the craftsmen who made the windows of medieval English churches and cathedrals were imported from the Continent, like Laurence Vitrearius (Glassmaker), a Norman who created the windows in the east end of Westminster Abbey.69

The third Gothic element, the flying buttress, was originally devised to shore up Romanesque walls threatening to collapse outward. Conventional buttresses—extra thicknesses added to walls at weak points—had been employed since Roman times but were unusable in a church with side aisles. The flying buttress proved not only an effective but an elegant solution. Leaping airily over the low side aisle, it caught the nave vault at the critical point where the outward-thrusting arch came to rest on the pier. The two thrusts neatly counterbalanced each other.70 That the flying buttress was also an aesthetic triumph was accidental but quickly recognized. Incorporated in the original design of Notre Dame de Paris, it proved a crowning touch. Stone caps, added to press the buttress down firmly, came as another aesthetically happy accident. Builders soon realized that interior piers could now be made slimmer. Thus innovations based on engineering imperatives rather than religious or artistic considerations provided the basis for the impressive new combination of religious expression and architecture.

Double flying buttress at Rheims Cathedral, as sketched by thirteenth-century master mason Villard de Honnecourt. [From The Notebook of Villard de Honnecourt, ed. by Theodore Bowie, Indiana University Press.]

From St. Denis, Durham, and Notre Dame de Paris, the new style spread across northwest Europe. In its final form, the Gothic church rose from a ground plan in the form of a cross, with nave (space for the congregation) and choir (space for the clergy) separated by a transept, and with an apse at the eastern end, usually consisting of an ambulatory and a number of chapels.

Abbot Suger’s memoir describes some of the procedures in the rebuilding of his church of St. Denis. The discovery of a new quarry “through a gift of God” yielded “very strong stone” for the construction. Equally providential was the arrival of “a skillful crowd of masons, stonecutters, sculptors, and other workmen.” The abbot himself and his carpenters scoured the abbey’s forests for suitable timbers for the roof and regarded it as a miracle when they found the twelve great beams they needed. “Moreover, it was cunningly provided” that the old nave and the old side aisles should be correctly aligned with the new ones “by means of geometrical and arithmetical instruments,” while the circular string of chapels in the ambulatory would make the whole church shine “with the wonderful and uninterrupted light of most sacred windows, pervading the interior beauty.”71

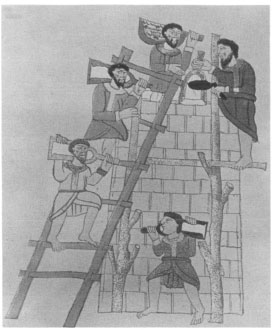

One detailed description of the construction of a twelfth-century church has survived from an account of the rebuilding of Canterbury Cathedral following a disastrous fire in 1174.72 In his “Tract on the Burning and Repair of the Church of Canterbury,” Gervase of Canterbury describes the arrival “amongst other workmen” of “a certain William of Sens, a man active and ready and as a workman most skillful both in wood and stone,” of “lively genius and good reputation.” Other “French and English artificers,” already consulted, had given contradictory advice. William studied the precarious state of the surviving parts of the church and determined that the entire structure must be razed and rebuilt from the ground up. He waited, however, until the monks had recovered from the shock of the holocaust before he gave his report, meanwhile “preparing all things that were needful for the work.” The monks, daunted by the prospect of a complete rebuilding, nevertheless consented “patiently, if not willingly,” and William set to work, importing stone from the Continent—probably from Caen, in Normandy, a prime source of building stone—and preparing “molds for shaping the stones” for the assembled sculptors. Meanwhile the choir of the old church was razed.

Twelfth-century building construction is shown in representation of the Biblical Tower of Babel. No lifting machinery is in evidence, masons carry hods, and primitive scaffolding is made from tree trunks. [Division of Rare and Manuscript Collections, Carl A. Kroch Library, Cornell University.]

Gervase describes the course of the reconstruction year by year: in the second year, 1175, the pillars and arches of the choir and the vaults over the side aisles were erected; in the following year, the main pillars at the meeting of choir and crossing and the gallery (triforium) above; the next year ten pillars of the nave and their corresponding arches and triforium.

William of Sens’s choir, Canterbury Cathedral. [Royal Commission on the Historical Monuments of England.]

One day in the fifth year of construction, William had climbed the timber falsework to the height of some fifty feet to direct the placing of “machines for the turning of the great vault,” when the scaffold gave way under his feet and he plunged to the floor amid a shower of stones and timber. Bruised and shaken, he took to his bed. The doctor was summoned, but the patient’s condition did not improve. With winter approaching and the upper vault yet to be finished, William chose “a certain ingenious and industrious monk” as his assistant and directed the work through him, an arrangement that caused some “envy and malice” among the other workers. When recovery continued to elude William, he resigned his post and returned to France. He was succeeded by another William, called “the Englishman,” “small in body, but in workmanship of many kinds acute and honest.” Under him the work proceeded for five more years. First the choir was finished and the altars erected so that Easter service might be performed there immediately. Later the exterior walls were built, a new crypt was completed, and the tower raised. “In the ninth year [1184] no work was done for want of funds.” In the tenth the cathedral was at last finished, the tower covered over, and the roofs protected with lead.

Gervase summed up the improvements of the new Gothic-style church over the old. The whole structure was much higher; the new pillars were taller; their capitals were sculptured where the old ones were plain. Marble columns were added, and the vaults were arch ribbed, with keystones. For the wall that had separated the choir from the transept, hiding it from the nave, were substituted pillars and a vault that left it open to view. Instead of a wooden ceiling, the church was covered with “a vault beautifully constructed of stone and light tufa [porous limestone],” and a second triforium gallery was added in the choir and two more in the side aisles of the nave. The effect was one of height, space, decoration, and light.72

St. Bernard, whose Cistercian Order played a leading role in diffusing the Gothic style, thought the soaring height and sumptuous ornamentation inappropriate for monastic buildings, but even St. Bernard could see the value for the laity of the Bible in glass and stone.73

Castle, Trebuchet, and Crossbow

The period that witnessed the evolution of Gothic architecture saw equally impressive advances in military engineering. Development of the masonry castle that largely supplanted the old timber motte-and-bailey was not stimulated by increased peril from outside. On the contrary, it coincided with the conversion of the Vikings into peaceful settlers and traders, and with Europe’s taking the offensive against Islam in the Mediterranean, in Spain, and with the First Crusade (1095–1099), in the Levant.

Rochester Castle, rectangular keep with a parapet 113 feet high, built in 1130. The round tower at left replaced a square tower undermined by King John in the siege of 1215.

What may have been the first stone “keep” in Europe was built by Fulk Nerra, count of Anjou (c. 970–1040) at Langeais, on the Loire near Tours, about the year 1000. In the eleventh century many more such keeps appeared, lofty, formidable, threatening, and like the cathedrals enduring monuments of the age. Square or rectangular in plan, the keep was usually three stories high, built of stone blocks in courses enclosing a rubble core, the floors timber, the windows few and narrow. Another type of masonry castle, the “shell keep,” appeared a little later: a circular stone wall, sometimes crowning a mound, within which living quarters were built in timber or stone.74

The rectangular keep and shell keep reflected the new feudal order, in which Europe was ruled by local lords whose castle-domiciles commanded the surrounding countryside. In England at the accession of Henry II in 1154, the king held 49 castles, the barons of the realm 225. The gradual shift of power toward the king may be read in the figures of sixty years later, at the time of Magna Carta: 93 royal castles, 179 baronial.75

Shell keep at Gisors, Normandy, early twelfth century, built on an artificial mound forty-five feet high. Four-story octagonal tower was added later by English king Henry II.

These fortresses were not, however, the last word in castle architecture. The advance to the final stage resulted in no small measure from the First Crusade. By leaving a few thousand knights and men-at-arms marooned in Syria and Palestine amid a sea of hostile Saracens, the Crusade placed a tremendous burden on defensive fortifications. Enriching their own European experience with ideas borrowed from the enemy—entrance traps, concentric walls, inner keeps76—the Crusading orders of the Templars and Hospitalers lined the frontiers of Syria and Palestine with castles that were the engineering marvels of the age, sometimes built from scratch, sometimes by enlarging, repairing, and elaborating captured Arab fortresses. Where earlier castle builders in Europe had paid scant attention to terrain, the Crusader castles were carefully sited on high ground, their few approaches cleared of cover and broken by a deep ditch (the moat). The corners of the rectangular keep were vulnerable to sappers digging under them and offered “dead ground” for attackers armed with battering rams to shelter out of reach of the garrison’s missiles; the Crusading castles, copying Byzantine and Saracen models, gave their corners round or multisided towers that effectively resisted both threats.77

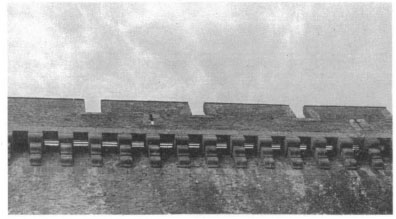

The main line of defense of the new castle was its high curtain wall, whose parapet was protected by crenellated battlements and provided with machicolations, another borrowing from the Arab enemy—openings in the floor through which missiles and boiling liquids could be dropped. Firing windows, called “arrow loops” or meurtrières (murderesses) were flared to the inside, giving the defending archer room to move laterally, with a wide field of fire, while presenting to the besieger only a narrow exterior slit as a target.

Crenellated curtain wall, with machicolations—openings through which missiles could be dropped. Fougères, Brittany.

Entry to the castle was through a gatehouse, whose portcullis, oak plated and shod with iron, was raised vertically by a pulley operated from an upper chamber in the gatehouse. Spanning the moat was a bridge with a draw section operated by counterweight. A device unknown to the Romans, the drawbridge was forgotten after the Middle Ages until revived by nineteenth-century bridge engineers for its modern purpose of spanning busy waterways. Sometimes the entry was through a skewed passage where infiltrators might find themselves trapped under fire from archers above them. If the outer wall was breached, the defenders could still fall back to the inner keep, with its own well-planned fields of fire.

A firing window or arrow loop flared to the inside (with late modification for guns). Falaise, Normandy.

The most famous of all the twelfth-century castles in Europe and Syria was the Krak des Chevaliers (Citadel of the Knights). Built by the Hospitalers in the first half of the twelfth century on the spur of a mountain, its massive walls formed two concentric rings dominated by great towers and separated by a wide moat. In addition to meurtrières, crenellations, and machicolations, the castle’s walls bore a less ferocious piece of technology, a windmill to grind the garrison’s grain.78 Besieged at least a dozen times, the Krak resisted every assault and continued to “stick like a bone in the very throat” of the Saracens, in the words of a Muslim writer,79 until in 1271, one of the last European strongholds in Asia Minor, it was captured by a ruse. The Muslim general Baibars tricked the garrison with a forged order and afterward chivalrously provided them with safe-conduct to the coast.80

The Krak des Chevaliers (Citadel of the Knights), Crusader castle in the Holy Land. [From Kenneth M. Setton, ed., A History of the Crusades, University of Wisconsin Press.]

The living quarters of twelfth-century castles featured a device that was immediately and widely copied: the wall fireplace. A marked improvement in efficiency over the old central hearth, the fireplace provided heat both directly and by radiation from its own stones and from the wall opposite. Late in the century, a projecting hood was added to better control the smoke, and the sides of the hearth were splayed to increase radiation. Whether in a castle or in a house, the fireplace was immense by modern standards, designed to accommodate large, long-burning logs.81

Despite their size and complexity, castles were often built with impressive speed if the need was urgent and the financial resources were available. Richard Lionheart’s Château Gaillard on the Seine was essentially built in a single year.82

Wall fireplace in great hall of the early-twelfth-century square keep at Vire, Normandy.

To attack or defend a castle, missile weapons were indispensable, and the period that initiated the building of castles also saw the introduction of a new form of artillery. A version of the trebuchet employing human traction to power the firing beam was invented in China as early as the first century A.D. and possibly passed via the Turks to the Arabs and Byzantines.83 Whether Parisians employed it against the besieging Vikings in the ninth century is a minor scholarly controversy. In the period between 1180 and 1220, the trebuchet was given a decisive improvement in Europe by the substitution of a huge counterweight for the manpower brigade. The machine’s arm was mounted asymmetrically on a fulcrum, with the short end, pointing toward the target, given the counterweight. The long end, wound back by a winch, was released by a blow from a mallet. The missile was carried in a sling, attached by long lines and lying at rest in a trough under the machine; when triggered, the beam sprang upward through an arc, gaining acceleration before the missile was picked up. Consequently, high “muzzle velocity” could be achieved, especially if the missile was released at near the optimum angle of 45 degrees.

Loading a trebuchet, top left; adjustable counterweights are hidden behind melee at center. [The Pierpont Morgan Library, Maciejowski Bible, M. 638, f. 23r. (detail)]

A vast amount of experimentation, of which no record survives, must have gone into the development of the counterweight trebuchet. The counterweight was in the form of a hopper filled with earth or stone, specified in one source as “nine feet across and twelve feet deep.”84 Varying the weight controlled the range. Modern experiments comparing the trebuchet with its ancient forebears have shown the medieval weapon capable of hurling a much larger projectile, a mass of 100 to 150 kilograms (220 to 330 pounds) a distance of 150 meters (160 yards)85 The older catapults have shown greater range, up to 225 meters (245 yards), but only with a much lighter missile, one of 20 to 30 kilograms (44 to 66 pounds). To batter down heavy masonry walls, weight of projectile was much the more important consideration. The value attached to the trebuchet is reflected in the custom of giving each engine a name, such as those recorded for Edward I’s siege of Stirling in 1304: Vicar, Parson, War-Wolf, Gloucester, Belfry, Tout-le-monde.86

A different version of the same machine, the “mangonel,” appearing at the same time, had a lower “angle of departure,” giving its missile a flatter parabola. The effectiveness of trebuchet and mangonel is indicated by the absence after the tenth century of references to the old-fashioned torsion engines.87

An even more important missile weapon made its appearance in Italy in the eleventh century. The crossbow had been known to the Romans (and the Chinese) centuries earlier but had never been very effective in its ancient form and had disappeared from warfare. Its basic principle was that a bow set transversely on a stock, or crosspiece, could be bent farther and so develop greater muzzle velocity than a handbow. In its medieval reincarnation, the weapon was cocked by resting the bow on the ground with the stock upright; the archer placed his foot in a stirrup on the stock, stooped to catch the bowstring on a hook in his belt, and by straightening up bent the bow, using the strength of his whole upper body instead of merely that of his arm. The bowstring was brought back to a locking device on a groove in the stock and fitted to the bolt, a short, very thick arrow armed with a heavy iron tip.

The crossbow was more expensive than the ordinary bow and took longer to reload, but in castle defense both disadvantages were minimized. The archer could reload in safety, while in the economics of siege warfare, in which a garrison of a hundred was expected to hold out against thousands of attackers, high cost of individual equipment was justified.

An important improvement in the medieval crossbow may have been learned during the Crusades from the Saracen enemy (strangely, the Crusaders’ Byzantine allies in 1097 knew nothing of the weapon, which princess-chronicler Anna Comnena described as “a Frankish novelty” and “a truly diabolical machine”).88 Wood as bow material was strong in compression but weak in tension, and the outer part of a bent bow was under tension. The tension created by the strength of a man’s arm was easily resisted by a strong wood, such as yew. But the tension created by the crossbow’s bending could cause “slithers” to splinter away. A strip of animal sinew, usually the large ligament that runs along the spine of most mammals, was incorporated as a reinforcing layer on top of the wood, absorbing some of the tension. Such a “composite” bow was made even stronger by a layer of animal horn on the underside. The power of the new weapon alarmed the Church, which in the Lateran Council of 1139 anathematized its use (and for good measure that of bows in general) against Christians. “Naturally, this prohibition was very unevenly observed” (Philippe Contamine).89

The Brothers of the Bridge

Crusaders, pilgrims, and merchants were perpetually on the road, but travel in the age of the Crusades was not for the faint-hearted. A tenth-century wayfarer described his journey from Constantinople to Lepanto, Greece, a distance of some five hundred miles, in these terms: “On mule-back, on foot, on horseback, fasting, suffering from thirst, sighing, weeping, lamenting, I arrived after forty-nine days.”90 By that time it was evident that the old Roman road network was out of date as well as out of repair. Its steep grades hindered merchants’ carts and pack animals, and its crumbling surfaces challenged even unencumbered travelers. Many of the routes, designed to serve Roman garrisons, no longer went where people wanted to go, while the new and growing traffic of medieval pilgrims needed roads to places the pagans had never sought to visit—Canterbury, Compostela, Roc Amadour.

As medieval commercial expansion altered the ratio of traffic, wheeled vehicles for the first time demanded a substantial share of the road. Certain kinds of merchandise suffered from rough surfaces. The tight-fitting wooden barrels that had replaced amphorae allowed wine to age properly but were likely to burst under severe jolts.91 How much road construction and maintenance was practiced in the central Middle Ages is unknown, but road builders did develop a surface of cobbles set in a thick cushion of sand that was better adapted to the northern climate than the rigid Roman pavement. As central and regional governments strengthened, roads under royal, imperial, or other seigneurial protection were most likely to receive attention. In England, royal roads were supposed to be maintained at a width sufficient for two wagons to pass, or for two oxherds to make their goads touch, or for sixteen armed knights to ride side by side.92 The only road built from scratch under the Norman kings of the eleventh and twelfth centuries was the one cut by Henry I in 1102 for the passage of his army over Wenlock Edge.93

By the twelfth century, the horse collar and harness had made the horse much the preferred traction for cart and wagon. Maneuverability was improved by several new or revived features: substitution of a pair of shafts for the old single draft pole; the whippletree, a transverse bar pivoted in the middle and positioned in front of the wagon (illustrated drawing a plow in the Bayeux Tapestry);94 and the pivoted front axle. Nailed horseshoes, common by the eleventh century, were mass-produced by the twelfth.95The spread of stirrups and saddles helped make riding easier and more popular.

In bridge construction, a tenth-century “nadir” (Marjorie Nice Boyer) was followed by a resurgence in the eleventh century.96 The eclipse of the Carolingian monarchy and the inheritance by local lords of the wardenship of river crossings opened up a new chapter in bridge building. Increased volume made toll collection an important source of revenue for many lords, while drawing attention to the inadequacy of ferries, where wagons, pack trains, droves of animals, and troops of the pious queued up to board the skiff or raft.

The Church intervened. Bishops began granting indulgences for bridge construction and repair, and the monastic orders took to collecting funds as well as maintaining hospices at crossings.97 Bridges also profited from inclusion in legacies, along with churches, hospitals, and “other pious and poor places.”98

In southeastern France in the twelfth century, a new, highly specialized order was founded by an ex-shepherd who became St. Bénézet, also known as Little Benedict the Bridgebuilder. The Frères Pontifes, or Brothers of the Bridge, built the Pont d’Avignon, whose twenty arches spanning the Rhône (and the island of Barthelasse) were of a new design, credited to Bénézet himself: elliptical, with the long axis vertical. The tall arches required less support during construction than the old Roman semicircular arches, permitting narrower piers in the stream. At the same time they provided more room for the rising waters of the notorious Rhône floods. The decrease in constriction reduced scour around the piling that underpinned the piers, the main threat to the stability of stone-arch bridges.99

Remaining four arches of the Pont d’Avignon, over the Rhône, built by the Brothers of the Bridge in the twelfth century. [French Government Tourist Office.]

Pont-St.-Esprit, another Brothers of the Bridge construction, with flattened segmental arches.

Near the Avignon end of his bridge, St. Bénézet built a combination of chapel and toll station, mingling piety with practicality in a graceful symbol. The Brothers of the Bridge raised funds and oversaw construction of at least two other large stone-arch bridges, at Lyons and Pont-St.-Esprit. The St. Esprit span introduced a design new to Europe, though long known in China: the flattened segmental arch (based on an arc smaller than a semicircle). The opposite of St. Bénézet’s tall arch, it was difficult to construct and had been avoided by the conservative Romans, but once in place it derived superior stability from the smaller number of piers in the river and consequent reduction in scour.100 The St. Esprit arches, however, were only slightly flatter than semicircular, and the extent to which the bridge’s builders understood the advantage is hard to say. Until the fourteenth century, nearly all medieval bridges continued to employ the semicircular arch.